rent submersible pump factories

Latest articles

All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

rent submersible pump factories...

rent submersible pump factories 【rent submersible pump factories】

Read MoreSlurry Pump VS Mud Pump

rent submersible pump factories...

rent submersible pump factories 【rent submersible pump factories】

Read MoreIf you want to get more information about the slurry pumps for sale, welcome to target=_blank title=Contact Us>contact us.

rent submersible pump factories...

rent submersible pump factories 【rent submersible pump factories】

Read MoreWhen slurry pump working, which is the motor drives the impeller rotation. That is the impeller on the slurry work which increases the kinetic energy of the slurry. At the same time, the slurry flows to the edge of the impeller due to inertia and is discharged from the discharge pipe at a high speed.

rent submersible pump factories...

rent submersible pump factories 【rent submersible pump factories】

Read MoreDredge pumps are designed to transfer large quantities of fluids and solids.

rent submersible pump factories...

rent submersible pump factories 【rent submersible pump factories】

Read MoreHow to Choose a Dredging Pump or Slurry Pump

rent submersible pump factories...

rent submersible pump factories 【rent submersible pump factories】

Read MoreWhat are the materials used to construct the pump?

rent submersible pump factories...

rent submersible pump factories 【rent submersible pump factories】

Read MoreFloor drainage

rent submersible pump factories...

rent submersible pump factories 【rent submersible pump factories】

Read More- Low noise level - Operating underwater results in low noise or even silent operation.

rent submersible pump factories...

rent submersible pump factories 【rent submersible pump factories】

Read MoreIf pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

rent submersible pump factories...

rent submersible pump factories 【rent submersible pump factories】

Read More

Popular articles

- Slurry Pump

- Quenching is defined as the introduction of a neutral fluid (usually water or steam) into the atmospheric side of the seal to prevent the formation of solids that may interfere with movement or be used for other purposes.

- Compared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

- If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

- >Slurry pump impeller is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

- The FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

Latest articles

-

Floor drainage

-

>Slurry Pump

-

Although the focus of slurry pumps is often on the size and percentage of solids to be pumped, in many applications corrosion resistance is also an important factor in material selection. In such cases, the material chosen must provide adequate resistance to erosion and corrosion.

-

Choosing Dry Slurry Pumps Versus Submersible Slurry Pumps

-

testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

-

It is often used if a short period of dry running is expected. Fluid is introduced into the area between the back of the seal face and the tight-fitting outlet on the drive side of the slurry pump.

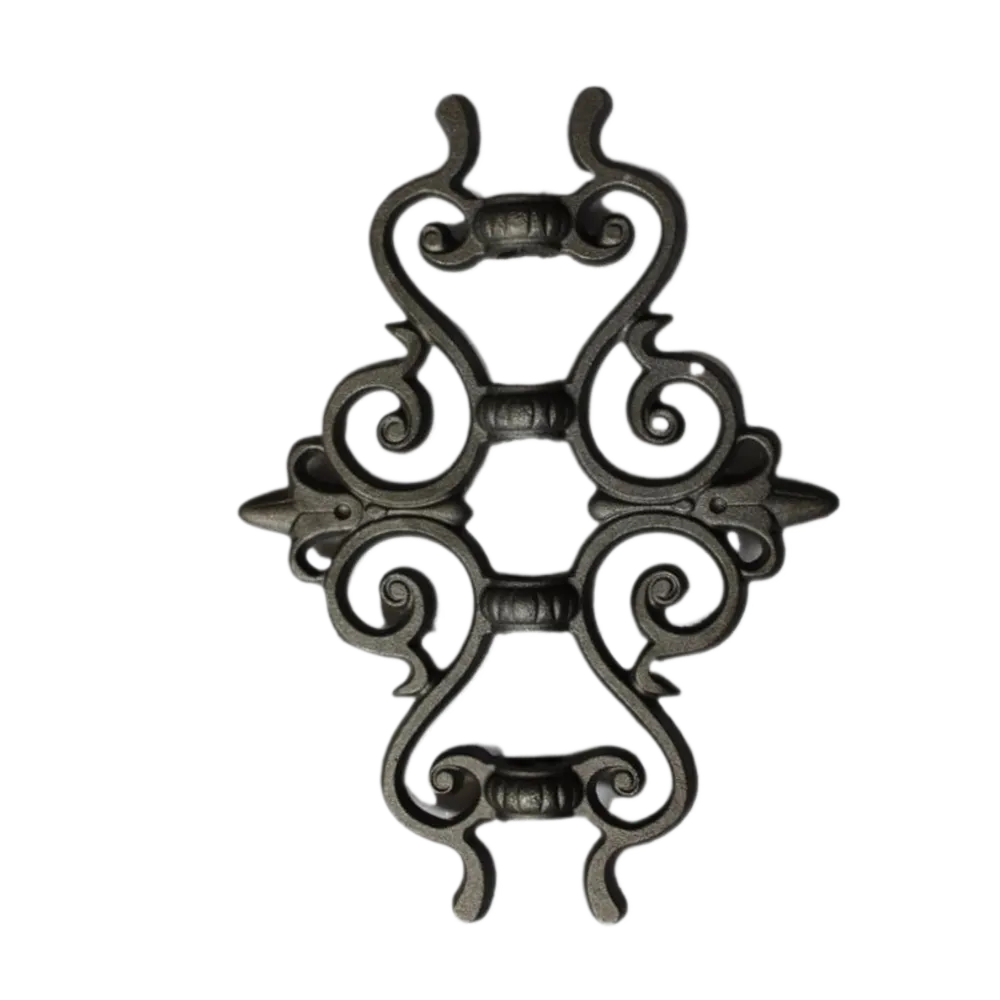

cast iron ornament. Unlike many other materials used in decorative arts, iron is resistant to corrosion and can withstand the elements, making it suitable for both indoor and outdoor use. This longevity ensures that these ornaments can be enjoyed for generations, often becoming cherished family heirlooms.

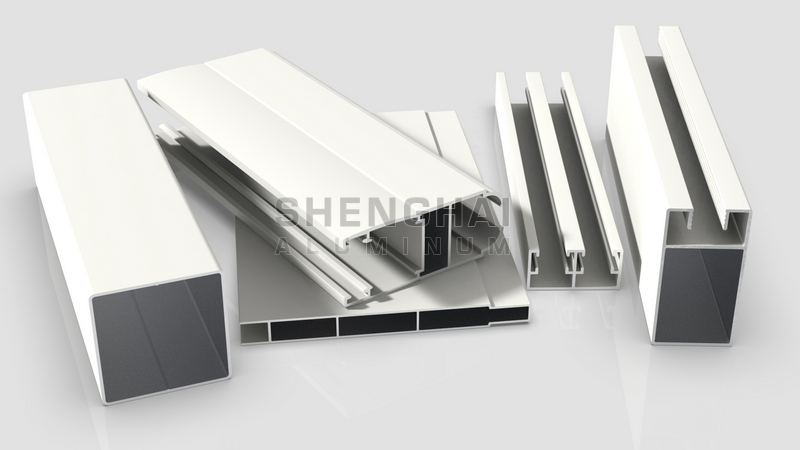

cast iron ornament. Unlike many other materials used in decorative arts, iron is resistant to corrosion and can withstand the elements, making it suitable for both indoor and outdoor use. This longevity ensures that these ornaments can be enjoyed for generations, often becoming cherished family heirlooms.Silver, champagne, Bronze, Golden, Black, White, Gray, Sand coating, Anodized Acid, Alkali, and wood texture, or Customized

aluminium sliding roller. Whether used in machinery that requires parts to remain stationary until activated or in conveyance systems that transport materials across large distances, these rollers provide the necessary support. They are particularly effective in linear motion applications, where their low-friction properties allow for smooth gliding actions that prevent jerky movements or misalignments.

aluminium sliding roller. Whether used in machinery that requires parts to remain stationary until activated or in conveyance systems that transport materials across large distances, these rollers provide the necessary support. They are particularly effective in linear motion applications, where their low-friction properties allow for smooth gliding actions that prevent jerky movements or misalignments.Check the available prices for these panels. Galvanized and powder coated. Fully Welded.

WHAT ARE THE TYPES OF ALUMINIUM WINDOWS?

Their non-porous surface makes them easy to clean, reducing the risk of bacterial buildup, particularly important in public spaces Their non-porous surface makes them easy to clean, reducing the risk of bacterial buildup, particularly important in public spaces

Their non-porous surface makes them easy to clean, reducing the risk of bacterial buildup, particularly important in public spaces Their non-porous surface makes them easy to clean, reducing the risk of bacterial buildup, particularly important in public spaces ss gate handle. Additionally, their sturdy construction ensures that they can withstand forceful attempts, providing an added layer of security.

ss gate handle. Additionally, their sturdy construction ensures that they can withstand forceful attempts, providing an added layer of security. Their non-porous surface makes them easy to clean, reducing the risk of bacterial buildup, particularly important in public spaces Their non-porous surface makes them easy to clean, reducing the risk of bacterial buildup, particularly important in public spaces

Their non-porous surface makes them easy to clean, reducing the risk of bacterial buildup, particularly important in public spaces Their non-porous surface makes them easy to clean, reducing the risk of bacterial buildup, particularly important in public spaces ss gate handle. Additionally, their sturdy construction ensures that they can withstand forceful attempts, providing an added layer of security.

ss gate handle. Additionally, their sturdy construction ensures that they can withstand forceful attempts, providing an added layer of security.

wheels for a sliding door. Wheels with a ball-bearing design are known for their smooth and quiet operation, making them an ideal choice for sliding doors in residential and commercial spaces. Additionally, wheels with adjustable height and width options provide flexibility in installation and ensure a perfect fit for the door.

The performance of windows and doors depending on the range of use, but the following aspects are usually considered: strength, which is mainly reflected in the selection of materials for windows and doors, whether it can withstand ultra-high pressure; air tightness, mainly in the structure of windows and doors, whether the inner and outer frames of the windows and doors are tight, and the doors and windows are tight.

Conclusion

Step-by-Step Guide to Adjusting Rollers

metal security box for car keys. It can be used to store not only car keys but also other valuable items such as credit cards, passports, and other important documents. This makes it a versatile solution for anyone who wants to keep their valuables safe and secure.

metal security box for car keys. It can be used to store not only car keys but also other valuable items such as credit cards, passports, and other important documents. This makes it a versatile solution for anyone who wants to keep their valuables safe and secure.Design and Aesthetics

Begin by removing any gates or detachable panels. If the fence sections are bolted together, use a wrench or socket set to loosen and remove the bolts. For welded joints, a grinder may be required to cut through the metal. Work systematically from one section to another to keep the process organized.

In addition to their practical and aesthetic qualities, wrought iron railing panels also contribute to the sustainability narrative

. The material is recyclable, and well-maintained panels can last for generations, reducing the need for frequent replacements and minimizing waste.Lightweight

Learn more about your options and ways to go about how to dispose of a wrought iron fence in our guide below.

Decorative wrought iron fence panels are a stylish and elegant way to enhance the look of any property. These ornate panels are not only functional for providing security and privacy, but they also add a touch of sophistication to any outdoor space.

5. Compliance with standard specifications

In conclusion, slimline aluminium profiles represent a perfect amalgamation of modern aesthetics and functional strength. Their versatility, durability, and attractive appearance make them an ideal choice for a wide range of applications across different sectors. As the demand for innovative, sustainable design continues to grow, the slimline aluminium profile is poised to play an even more central role in shaping the built environment of the future. Whether for homes, offices, or commercial spaces, these profiles provide an elegant solution that meets the needs of today’s dynamic design landscape.